Branches Profile

Mabuchi’s core competence in packing solutions has brought the company to become a renowned packing suppliers Malaysia and Singapore company by adopting quality packing materials Malaysia and Singapore in our services. Our services are unique in a way that we provide customized packaging solutions to our customers. To us, each job is unique and specially designed packing methods to suit the items to keep it safe upon arriving to its destination.

Packing Services – Carton Box Packing

Carton Box Packing

Part : Steel Automotive Part

Step 1 : Tape bottom carton box with Opp Tape, then put PP Hollow Pad (white) inside the carton box.

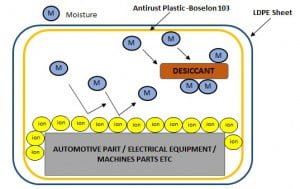

Step 2 : Apply LDPE Sheet on top of the carton box.

Step 3 : Apply Antirust Plastic Boselon Sheet on the LDPE Sheet.

Step 4 : Put part on the Boselon Sheet.

Step 5 : Put 1 pc Desiccant of Silica Gel or SUNDRY on the part.

Step 6 : Wrap the part with Boselon Sheet.

![file-page2[1]](http://mabuchi-indonesia.co.id//wp-content/uploads/2016/04/file-page21-300x236.jpg)

Step 7 : Wrap with LDPE Sheet and tape use Opp Tape.

Step 8 : Closed the box and tape it.

Box Packing was completed. 🙂

PP Strapping Band + Poly Plastic Buckles

Method to fix PP Strapping Band with Poly Plastic Buckles

Items : 2 unit Carton Box , 2pcs PP Strapping Band (Yellow) , 2pcs Poly Plastic Buckles

Step 1 : Arrange carton box and set PP Strapping Band at the bottom.

Step 2 : Fold one side PP Strapping Band

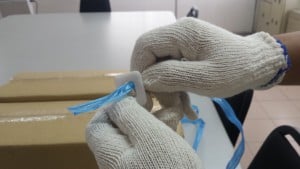

Step 3 : Insert into Poly Plastic Buckles

Step 4 : Tighten the PP Strapping Band with Poly Plastic Buckles

Step 5 : Repeat step 2 until step 4 for one more side

Step 6 : Tighten both side of PP Strapping Band

Step 7 : To make it neat, fold the PP Strapping Band as photos below

Step 8 : Repeat step no.2 until no.7 for one more PP Strapping Band

Assembly finished.

We can use PP Strapping band + Poly Plastic Buckles in a variety application including general packing , Food industrial , newspaper , corrugated boxes , paper board and etc.

Let use it 🙂

——————————————————————————–

Item : PP Pand (Yellow) vs Poly Pail Band (Blue)

Price : Low vs High

Reuse : One time use vs Re-use

Elasticity : No vs Yes

Toughness : Weak vs Strong

——————————————————————————–

Packing Service – Carton Case Packing

Packing Service – Carton Box + Carton Case + Plywood Base

Item for Packing: 1 unit Transmission

Material usage

Plywood base, Top & Bottom carton tray, Sleeve, LDPE Plastic Sheet, PP Hollow, Paper Edge Protector ,EPS Block , Antirust Plastic Boselon, Silica Gel, Carton box and Tape.

Step 1 : Order or make a RSC Carton box.

Step 2 : Set up PP Hollow inside carton box.

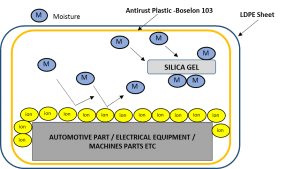

Step 3 : Apply LDPE Plastic Sheet.

Step 4 : Apply Antirust Plastic Boselon.

Step 5 : Transfer the Transmission into carton box and put 1 pc Silica gel.

Step 6 : Cover the LDPE Plastic Sheet and tape.

Step 7 : Tape the carton box and paste tagging.

Step 8 : Apply LDPE Plastic Sheet onto Plywood carton base.

Step 9 : Put the carton box onto Plywood carton base and wrapped the plastic.

Step 10 : Apply Sleeve and install EPS Block the box.

Step 11 : Apply Paper Edge Protector and top tray.

Step 12 : Use Heavy Band to tighten between plywood base with Carton Tray. Then wrap it using Cast Stretch Film and paste packaging mark.

Packing done.

Good Packaging  Protection for internal & External Packing.

Protection for internal & External Packing.

Poly Pail Band + Plastic Clip

Method to tie Poly Pail Band with Plastic Clip

Items : 2 pcs Carton Box , 2 pcs Poly Pail Band (Blue) and 2pcs Plastic Clip

Step 1 : Tie Poly Pail Band with Plastic Clip as photo below.

Step 2 : Tie one more time and tighten the Poly Pail Band

Step 3 : Arrange the Poly Pail Band at the bottom carton box.

Step 4 : Tighten the Poly Pail Band with Plastic Clip 2x time. Than tie it.

Step 5 : Pull end of the Band to make more tighten.

Step 6 : Repeat step 1 until step 5 for one more Poly Pail Band.

Lets try use Poly Pail Band with Plastic Clip. 🙂

- We can use Poly Pail Band with Plastic Clip in a variety application including in general packing, Food industrial, News paper, Corrugated Boxes , Paper Board and etc.

———————————————————————————————–

Item : Poly Pail band (Blue) vs PP Strapping Band (Yellow)

Price : High vs Low

Reuse : Re-use vs One time use

Elasticity : Yes vs No

Toughness : Strong vs Weak

———————————————————————————————–

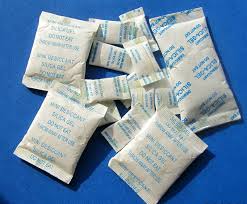

Desiccant – Silica Gel

Silica Gel

Silica gel is a granular, vitreous, porous form of silicon dioxide made synthetically from sodium silicate. it is used as a desiccant to control local humidity to avoid spoilage or degradation of some goods.The main application of Silica Gel is to attract and hold water, alcohol, hydrocarbons and other chemicals by the phenomena known as physical adsorption and capillary condensation. It generally uses for various products such as auto parts, electrical, appliances, electronics, food packing, furniture and footwear. Silica Gel available in different packet size (1g – 1000g).

Silica Gel – Absorbing moisture

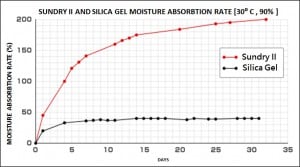

Silica gel vs Sundry II

| Description | Silica Gel | Sundry II |

| Price | Cheap | Expensive |

| Quantity usage | More quantity | Less quantity |

| Absorb Moisture level | Low | High |

| Re-use | Can | Can not |

| Usage | include food packing | except food packaging. |

Moisture Absorbtion rate between Silica gel & Sundry II

Make sure we choose the right desiccant for packing our product. ![]()

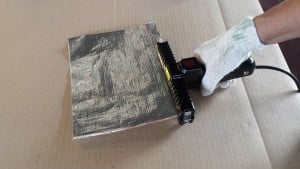

Aluminium Barrier Bag Fabrication

How to fabricate Aluminium Barrier Bag

Two type of Aluminium Barrier Bag

Type 1: Two side seal bag

Type 2 : Quad Seal bag

Aluminium Barrier bag Fabrication Type 1.

Step 1 : Prepare materials and tools

Material: Aluminium Barrier Sheet

Tools : Knife, Ruler,Hand Sealer and Glove

Step 2 : Cut Aluminium Barrier roll to cut size needs

Step 3 : Fold the Aluminium Barrier sheet .Than seal both side using Hand Sealer.

Step 4 : Two side seal Aluminium Barrier bag finished fabricated

____________________________________________________________________________________

Aluminium Barrier Bag Fabrication Type 2

Step 1 : Cut Aluminium roll to cut size needs

Step 2 : Fold the Aluminium Barrier sheet become 2 layer.Than cut base on dimension needs.

Step 3 : Seal right and left side.

Step 4 : Seal edge portion at both side.

Step 5 : Quad Seal Bag Fabrication completed.

Let try.

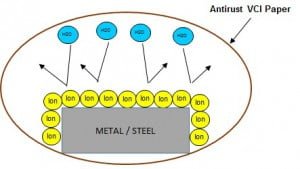

Anti Rust Paper

Anti Rust paper : Vapour Corrosion Inhibitors (VCI) Paper

VCI paper provides extensive and effective rust protection when shipping or storing metal parts. The vapor corrosion-inhibiting technology behind Rust Inhibitor Paper enables long-term protection on ferrous and non-ferrous metals, including iron, steel, cast iron, copper, brass, galvanized steel and zinc.

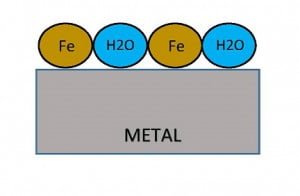

How VCI Works

The rust preventative paper known as VCI is coated with corrosion-inhibiting chemicals, which vaporize into the air around metal parts – through package or storage – and protect them from rust.

These corrosion-inhibiting chemicals work on a molecular level, as the VCI technology migrates from the paper into the packaging environment to create a thin layer of protection that adheres to all areas of a metal’s surface, including hard-to-reach areas like cracks, crevices, nooks and other irregularities.

How to use VCI paper for Packing

- Wrap metal parts in Rust Prevention Paper

- Place inside wooden crates, boxes or shipping containers

- Interleave Rust Inhibitor Paper between layers of parts or drape over parts

Metal Part Protected with VCI Paper

- Automotive parts

- Steel coils

- Wire

- Steel bars

- Steel tubing

- Steel forgings and die casting

- Raw and machined forgings and castings

- Metal stampings

- Springs

- Bearings

- Copper

- Brass

- Bronze

- Zinc

- Galvanized metal

- Powdered metal parts

- Engines

- Machinery

- Equipment

- Tools

- Instruments

- Motors

- Electronic components

- Controls

- Printed circuit boards

- And more

Advantages using VCI paper

1 – Reliable corrosion free

2 – Long term protection

3 – Cost saving

4 – No environment,health or safety hazards

5 – Simple and secure applications

6 – Approved by Global leader in the automotive industry

Anti rust paper roll can converted into sheets,bags and wrap for individual parts.Shrouds,cover and liners for large pieces of parts.

Let choose a more cost-effective and complete rust preventative solution.![]()

Stretch Film

Stretch film

Stretch film is coming in varying gauges,colors and can be use in numerous applications.Stretch film is wrapped around the load to provide stability. The film is stretched 200-300% while it is applied either by hand or machine. The properties of stretch film cause it to try and return to its original size, resulting in a tight and secure load for shipping. Stretch film also provides some protection from moisture and dust, can be a deterrent from pilferage, and improves stability of the load for internal handling. Stretch film is made of polyethylene plastic.

Hand films usually have minimal stretch (25-100%) in order to aid the operator in applying the product and are in many ways similar to a large roll of very thin tape. Machine films on the other hand can have very high stretch levels (150 -300%) and, because they are applied by automated equipment, can be configured to exert very high levels of tension on a load if desired.

In pallet unitizing, stretch wrap can have several functions:

- Improved stability of products or packages, forming a unit loads

- More efficient handling and storage of unit loads

- Dust and moisture protection

- some degree of tamper resistance and resistance to package pilferage

- some degree of sun protection (UV stretch wraps)

Application

Manual Wrapper (by Hand)

Intended for manual wrapping, the thickness of the manufactured film ranges from 10 to 40 micrometres and the width is 450 mm or 500 mm, guaranteed stretch is 100%, the film is wound on automatic machinery equipped with devices controlling both the length and the weight of film wound on the roll.

- Extended Core

- Mechanical Brake

- Pole Wrappers

1 . 2.

2.  3.

3.

Semi Automatic Wrappers

- Turtable Wrappers

- Orbital Wrappers

- Rotary Arm Wrappers

Automotic Wrappers

- Turntable Wrappers

- Rotary Arm Wrappers

- Rotary Ring Wrapper

1. 2.

2.  3.

3.

Types of stretch film include bundling stretch film, hand stretch film, extended core stretch film, machine stretch film and static dissipative film.

Lets choose suitable Stretch Film.

Paper Pallet

Paper Pallet

Paper pallets are shipping display pallet made from paperboard.

Paper shipping pallets come in corrugated fibreboard partial wood decks or engineered with laminated paperboard. Some are made of paperboard composite honeycomb.

Comparison between Paper Pallet and Wooden Pallet

| Description | Paper Pallet | Wooden Pallet |

| Price | Less | More |

| Weight | 70% lighter | Heavy |

| Load Capacity | Less than 1 tan or 500kg depend on pallet design | Able load more than 1 tan base on pallet design |

| Oversea Shipment | No need fumigation | Must fumigation |

| Recycle use | Not suitable to recycle use | Able to recycle use |

| Storage | Not suitable to storage outside warehouse in raining season | Able to storage outside |

Other benificial of Paper Pallet

* Made completely from kraft paper, paper pallets are totally recyclable.

*No hazardous gasses or chemicals used or emitted in manufacturing our pallet.

Sample Paper Pallet

*There are many different design configurations that exist within the paper pallet market that may use glue, staples and paper cores in their assembly, although designs have been engineered from just two flat corrugated boards.

You are welcome to discuss with us if you want different design of Paper Pallet.![]()

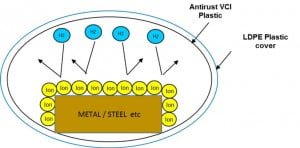

VCI anti rust plastic

VCI Anti Rust Plastic

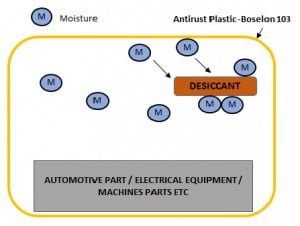

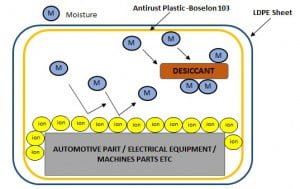

VCI plastic provides an extremely dry method of protection.It protects metals both through direct contact and vapour action. The hightech VCI chemicals have a property of evaporating into the surrounding enclosure. The released vapour deposits on the metal surface and forms a protective mono-ionic layer which provides protection to the packed parts from corrosion. It thus enables effective and long term protection of ferrous and non-ferrous metals against corrosion /oxidation and tarnishing under adverse conditions including contaminants in air such as hydrogen sulphide, sulphur dioxide, ammonia or acid rain. VCI vapours easily migrate to hard to reach areas like drilled holes, crevices etc. and give effective protection.

Advantages of VCI Plastic

1 – Corrosion resistance, VCI plastic wrappers provide protection against moisture, dust and contamination.

2 – Material packed in anti corrosive PE sheets does not require any other additional packing. sealrust® VCI poly sheets are almost Transparent, hence packed products can be easily identified.

3 – Sheets made out of low density polyethylene are dimensionally stable and can be folded and available in custom sizes thus suitable for all types and all sizes of products to be packe

4 – VCI Plastic wrappers are Economical compared to VCI Paper Wrappers and any other method used for corrosion protection.

5 – VCI plastics wrappers can withstand environmental abuse which VCI paper cannot.

6 – VCI Plastic wrapper material is water, oil, grease resistant while paper does not have any of these properties

Method of usage

1 – Clean the parts to be protected from dirt, dust and other contaminants.

2- Individual parts can be wrapped in VCI Film

3- Can be used in the form of 2 dimensional pouches, 3 dimensional bags and Tubing.

4 – Can be used as a box liner inside corrugated boxes, cartons, wooden boxes and containers.

5 – Seal package well, though not necessarily air tight for maximum benefit.

Packaging & Storage

1 – Store in a cool and dry place.

2 – Stable at normal storage conditions.

3 – Keep away from contaminants prior to usage.

4 – Store in original packing for optimum benefits.

Part for Application

1 – Metal – Coils / Sheets/ Pipes / Tubes/ Wires etc.

2 – Automotive – Pistons / Connecting Rod / Crankshafts / Camshafts / Engine assembly etc.

3 – Engineering – Palleted Castings / Forgings / Machined parts, Bearings, Spare parts, Tools.

4 – Electrical and Electronics – PCBs, Relays, Panels, etc.

5 – Defense – Marine / Aerospace equipments and parts.

Availability

1 – Available in rolls of standard thickness and width (100 mtrs).

2 – Available as Plain ,Cut sheets , 2 D Pouches and 3D bags.

3 – Custom size will be made upon request.