VCI anti rust plastic

VCI Anti Rust Plastic

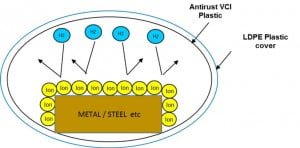

VCI plastic provides an extremely dry method of protection.It protects metals both through direct contact and vapour action. The hightech VCI chemicals have a property of evaporating into the surrounding enclosure. The released vapour deposits on the metal surface and forms a protective mono-ionic layer which provides protection to the packed parts from corrosion. It thus enables effective and long term protection of ferrous and non-ferrous metals against corrosion /oxidation and tarnishing under adverse conditions including contaminants in air such as hydrogen sulphide, sulphur dioxide, ammonia or acid rain. VCI vapours easily migrate to hard to reach areas like drilled holes, crevices etc. and give effective protection.

Advantages of VCI Plastic

1 – Corrosion resistance, VCI plastic wrappers provide protection against moisture, dust and contamination.

2 – Material packed in anti corrosive PE sheets does not require any other additional packing. sealrust® VCI poly sheets are almost Transparent, hence packed products can be easily identified.

3 – Sheets made out of low density polyethylene are dimensionally stable and can be folded and available in custom sizes thus suitable for all types and all sizes of products to be packe

4 – VCI Plastic wrappers are Economical compared to VCI Paper Wrappers and any other method used for corrosion protection.

5 – VCI plastics wrappers can withstand environmental abuse which VCI paper cannot.

6 – VCI Plastic wrapper material is water, oil, grease resistant while paper does not have any of these properties

Method of usage

1 – Clean the parts to be protected from dirt, dust and other contaminants.

2- Individual parts can be wrapped in VCI Film

3- Can be used in the form of 2 dimensional pouches, 3 dimensional bags and Tubing.

4 – Can be used as a box liner inside corrugated boxes, cartons, wooden boxes and containers.

5 – Seal package well, though not necessarily air tight for maximum benefit.

Packaging & Storage

1 – Store in a cool and dry place.

2 – Stable at normal storage conditions.

3 – Keep away from contaminants prior to usage.

4 – Store in original packing for optimum benefits.

Part for Application

1 – Metal – Coils / Sheets/ Pipes / Tubes/ Wires etc.

2 – Automotive – Pistons / Connecting Rod / Crankshafts / Camshafts / Engine assembly etc.

3 – Engineering – Palleted Castings / Forgings / Machined parts, Bearings, Spare parts, Tools.

4 – Electrical and Electronics – PCBs, Relays, Panels, etc.

5 – Defense – Marine / Aerospace equipments and parts.

Availability

1 – Available in rolls of standard thickness and width (100 mtrs).

2 – Available as Plain ,Cut sheets , 2 D Pouches and 3D bags.

3 – Custom size will be made upon request.